What We Do

Developing Our People for

Growing Our Business

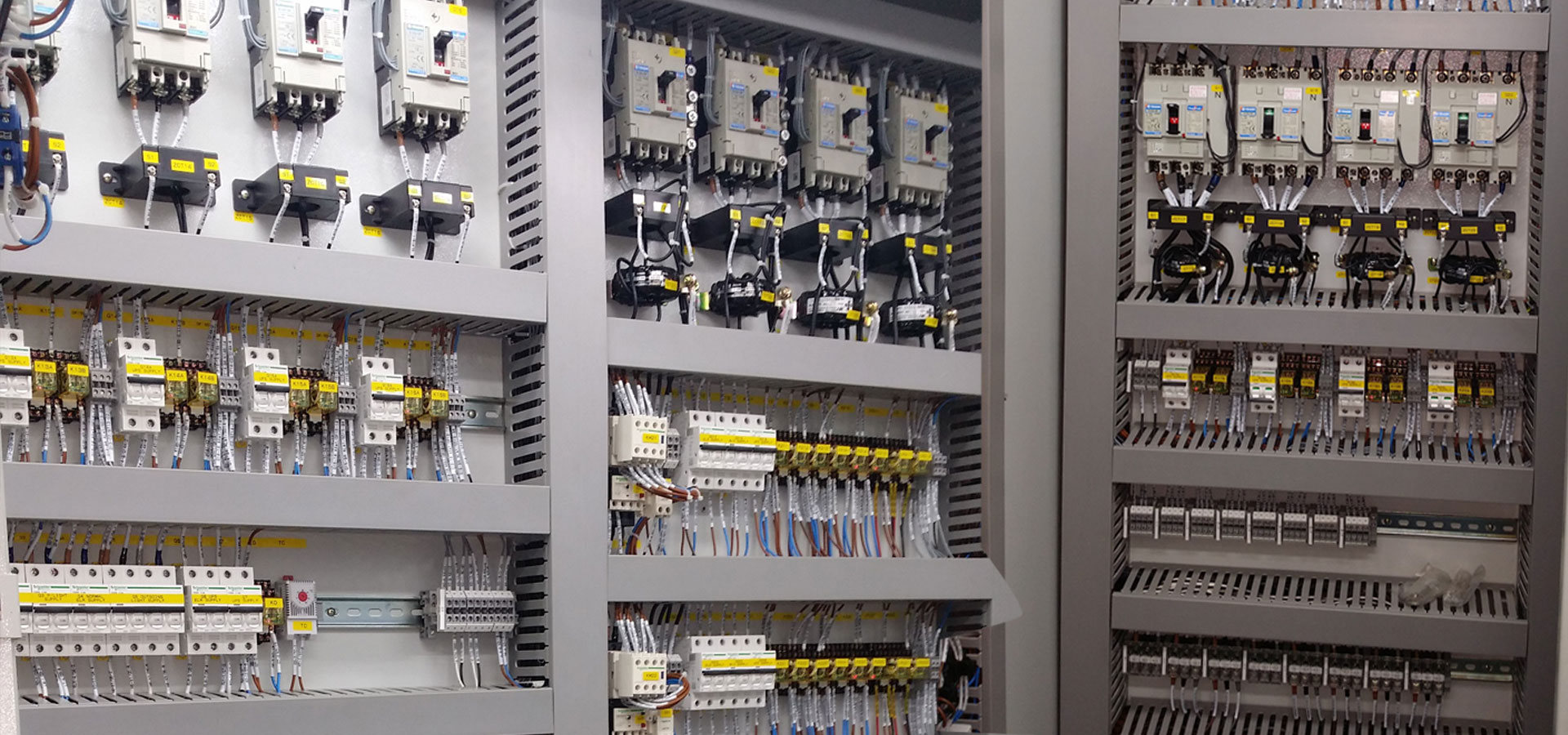

PECON is a Growing and Promising Singapore Company, we started our journey in 2011 to work with Process and related industries in the undertaking of Electrical and Instrumentation Engineering service and contracts. We strongly committed to offering suitable product and services to our valuable customer with highest efficiency and cost effectiveness for mutually beneficial thus bring in trust and relation.

Passion

We have the Passion for Customer Satisfaction through our Safety and Quality Standards

Integrity

We are committed to highest standards of Ethical & Professional behaviour in return

Excellence

We strive to excel in every possible aspect to meet and exceed obligations and expectations

Leadership

We are determined to bring up PECON to attain our Vision to reality through our people

Social Responsibility

We being a sincere corporate citizen understand our commitment to respect

Why Choose Us

We are 25 year experience

in industry

PECON is a Growing and Promising Singapore Company, we started our journey in 2011 to work with Process and related industries in the undertaking of Electrical and Instrumentation Engineering service and contracts. We strongly committed to offering suitable product and services to our valuable customer with highest efficiency and cost effectiveness for mutually beneficial thus bring in trust and relation.

Quality & Safety

Our Certifications

Our Objectives

PECON strongly committed to offering suitable product and services to our valuable customer.

PECON belief in importance of customer satisfaction and its drives us to put their needs at the centre of our mission.

PECON strive to deliver the Best in nature that we do by developing our products, and we committed to improving our process of delivering, and to providing outstanding quality service to meet the dynamic changes in need.